AX4-1623S

AX4-1623S

Couldn't load pickup availability

- 1 Pcs / 1 Set

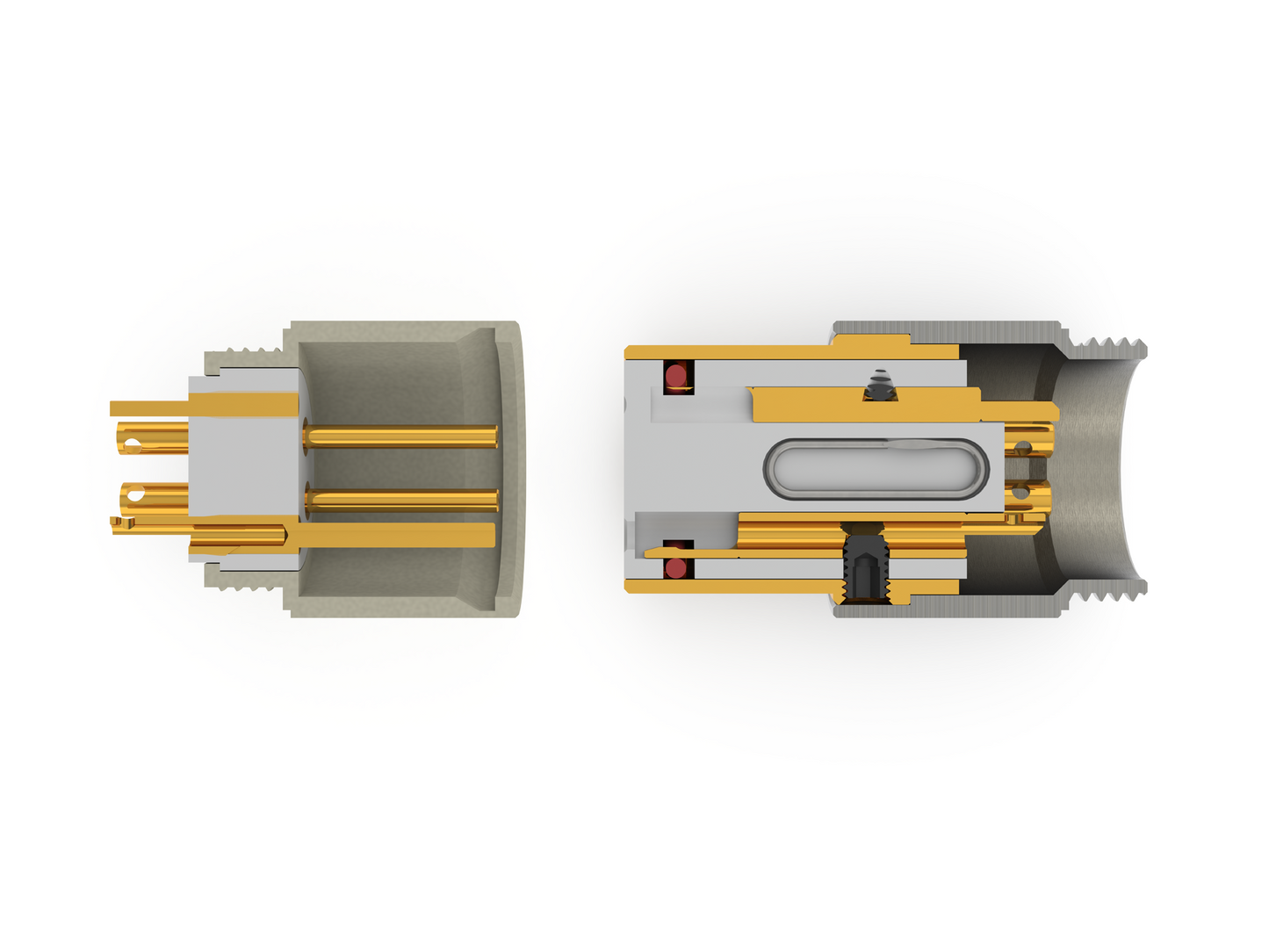

- "One Point Contact” structure.

- High-purity copper (TeCu).

- The product can be completely disassembled.

- Support 9/11.5/15mm cable hole.

※ The product image is for reference only; the actual shipped product shall prevail. ※

Note

Note

Do not remove the four black POM screws (161~164) on the body. Doing so will cause all parts of the unit to fall apart. These screws are for maintenance and recycling purposes only.

Screws with the finished products.

(6/4mm two screws per each.)

Concept

Concept

Non-coaxial conduction are able to use single point conduction while plug connect to jack.

Conductor between body isolate by PTFE insulator.

The conductor is made from high-purity tellurium copper without nickel plating.

The connector can be completely disassembled for maintenance and recycling.

Mechanical structure

Mechanical structure

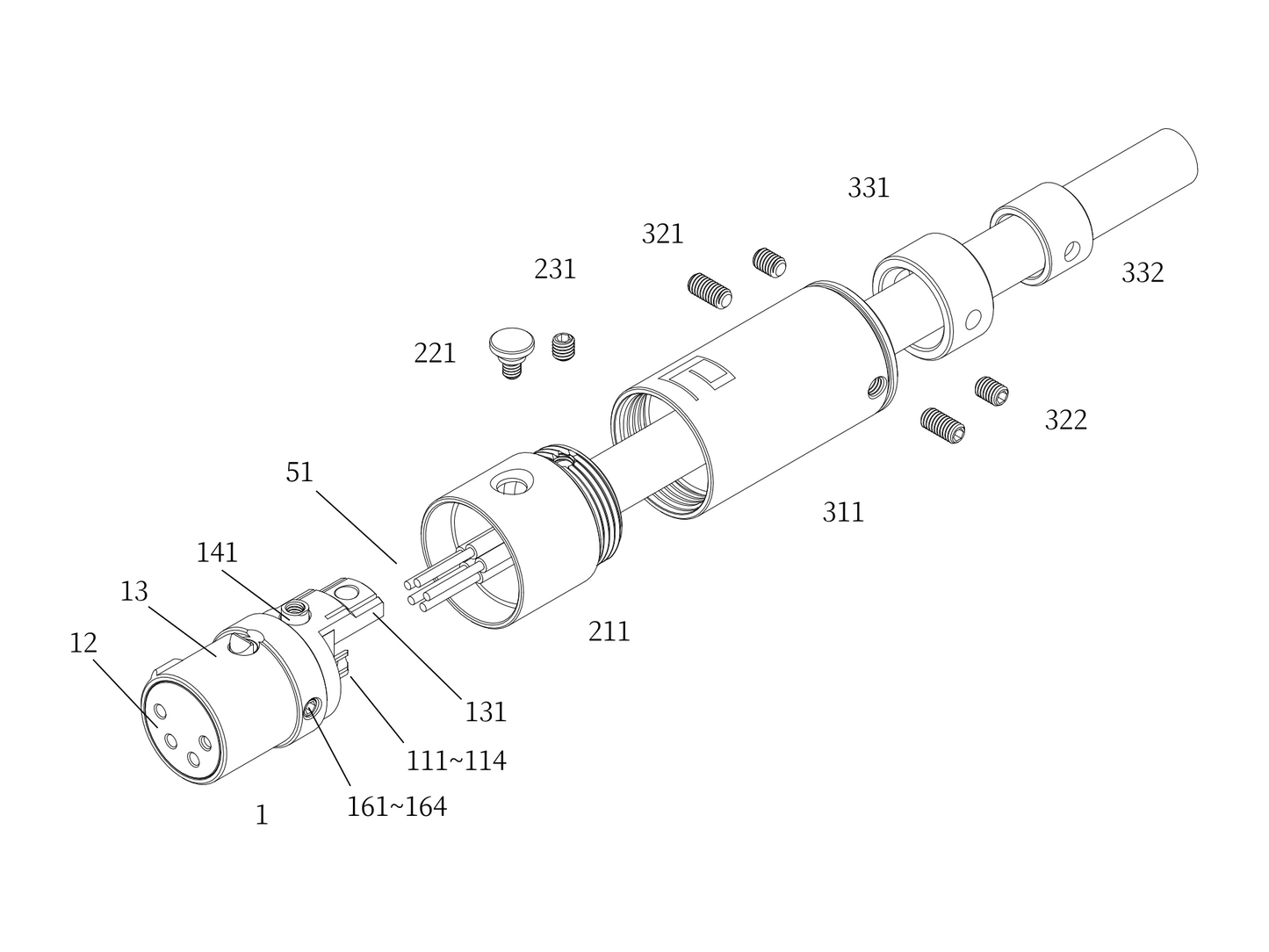

The spring and lock are placed in the insulator, the lock partially protrudes from the body, and each contact pin is secured to the body with each POM screw through the insulator, forming the body unit.

The body unit is screwed to the front shell and the button screw are threaded through the side hole of the front shell to secure the lock.

The body unit and back shell are threaded together, and the sleeve is screwed to the end of the shell with a hole diameter of 9.0/11.5mm, and the hole diameter of the shell is 15.0mm after the sleeve is removed.

Assembly

Assembly

1. Unthread the back shell [311] and front shell [211].

2. Peel off the cable [51] and each insulation of conductor.

3. Depending on the outer diameter of the cable, decide whether to use the sleeve (ID 9.0mm) [332], the sleeve (ID 11.5mm) [331], or only the back shell (ID 15.0mm).

4. Slide the sleeve and back shell over the cable.

5. Unscrew the body screw [231] on the front shell.

6. Push the body unit [1] out of the front shell [211] by pressing the inner thread side of the lock [141].

Refer to the video: Push out the body unit

7. Slide the front shell over the cable.

8. Solder the conductor on each signal pin. [111][112][113][114].

9. Solder the body grounding tab [131] as required.

10. Place the body unit into the front shell with press and slide the lock to the second layer of the front inner [141] and try to press it properly.

Refer to the video: Placing the Body Unit

11. Use the body screw [231] to secure the front shell to the body unit. Tighten the screw until it is secure, but be careful not to overtighten as this may cause the screw to fall into the inner diameter of the front shell.

12. Thread the back shell to the front shell.

13. Secure the cables with screws [321] or [322] through the shell and sleeve.

14. Secure the button screw [221] through the side holes of the front shell to the lock and try to press the button.

[51]'s 5th channel conductor, as the schematic diagram, it may means full coverage braided.

Specification

Specification

Material:

Contact Pin: Tellurium Copper(C14500 / copper contains over 99%)

Insulator: PTFE

Body: Brass alloy (C3604)

Spring: Stainless steel (SUS304)

Lock: Brass alloy (C3604)

Pin Screw: POM

Front Shell: Stainless steel (SUS304)

Button Screw: Stainless steel (SUS304)

Back Shell: Stainless steel (SUS304)

Sleeve: POM

Screw: Stainless steel (SUS304)

Finish:

Contact Pin: 120u" Silver plating (no nickel base)

Insulator: None

Body: 120u" Silver plating (no nickel base)

Spring: None

Lock: None

Pin Screw: None

Front Shell: None

Button Screw: None

Back Shell: None

Sleeve: None

Screw: None

Electrical Characteristics:

Contact resistance < 1.0 mOhm

Dimension:

Biggest OD: 18.9mm

Total Length: 62.8mm

Recommend soldering temperature

Recommend soldering temperature

Temperature Soldering Iron, please keep 340 °C within 3~5 second.

Product production process comply with RoHS.

Share