AT4-1812G

AT4-1812G

Couldn't load pickup availability

- 1 Pcs / 1 Set, Vacuum Bag

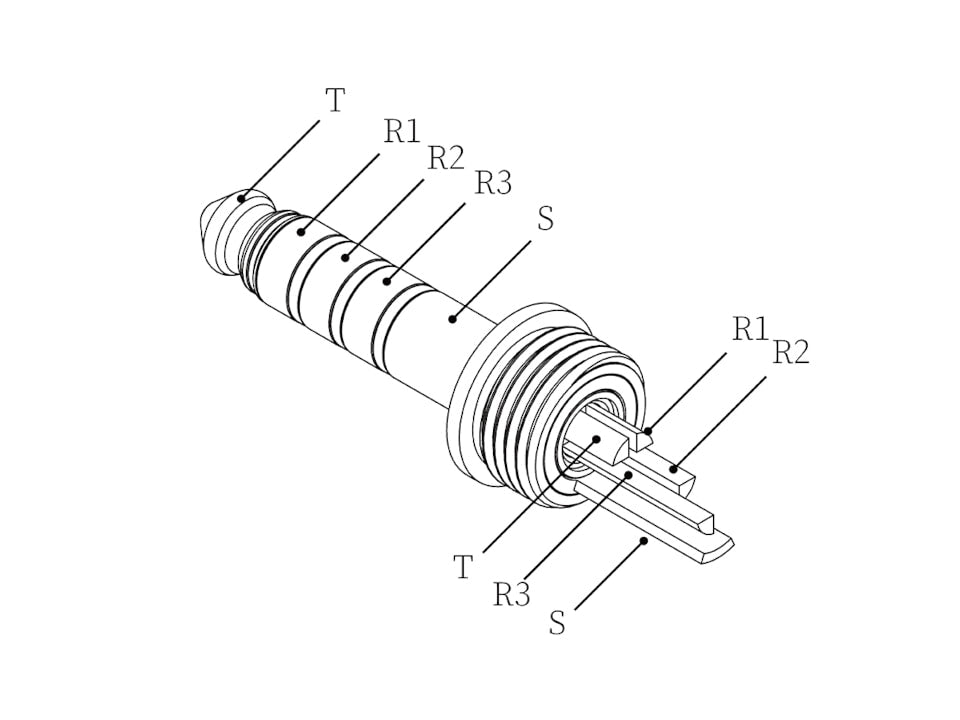

- Soldering pins of each channel and cable core wires are parallel oriented, it is far more convenient for soldering.

- 4 pole metal conductors (right, left, positive, negative ) with the same cross-sectional area.

- Made by CNC lathing as one shape.

- Shell can be isolated with body.

- High-purity copper(over 99%) made.

Note

Note

This product include: screw for cable 3 mm*1pcs and 4 mm*1pcs.

Over soldering time may cause expands or damage of insulation.

When soldering the contact pin, please follow up our suggested temperature.

Concept

Concept

One piece conductor is manufacture via CNC machining, in order to reduce the loss of signal that between each different conductors.

Soldering pins of each channel and cable core wires are parallel oriented, it is far more convenient for soldering.

4 pole metal conductors (right, left, positive, negative) with the same cross-sectional area.

Shell between body isolate by insulator material. Depends on the method of processing, it can choose to make the shell be a conductor.

The conductor is made from high-purity tellurium copper without nickel base.

By using highest quality of design techniques and material to provide customer who has "Hi-End" requirement.

Mechanical structure

Mechanical structure

4.4mm metal body with five parts, Tip Pin, center ring, end sleeve.

Each metal part is separate by Nylon insulation.

There’s a hole between the contact pin and body structure.

To put the fillers into the gap of the body from the hole.

Use the POM latch through to fix the body.

The body and the shell locked by screwing.

POM sleeve is fixed with end of shell by using screw.

Assembly

Assembly

1. We recommend to peel off the cable jacket and per conductor wire insulation.

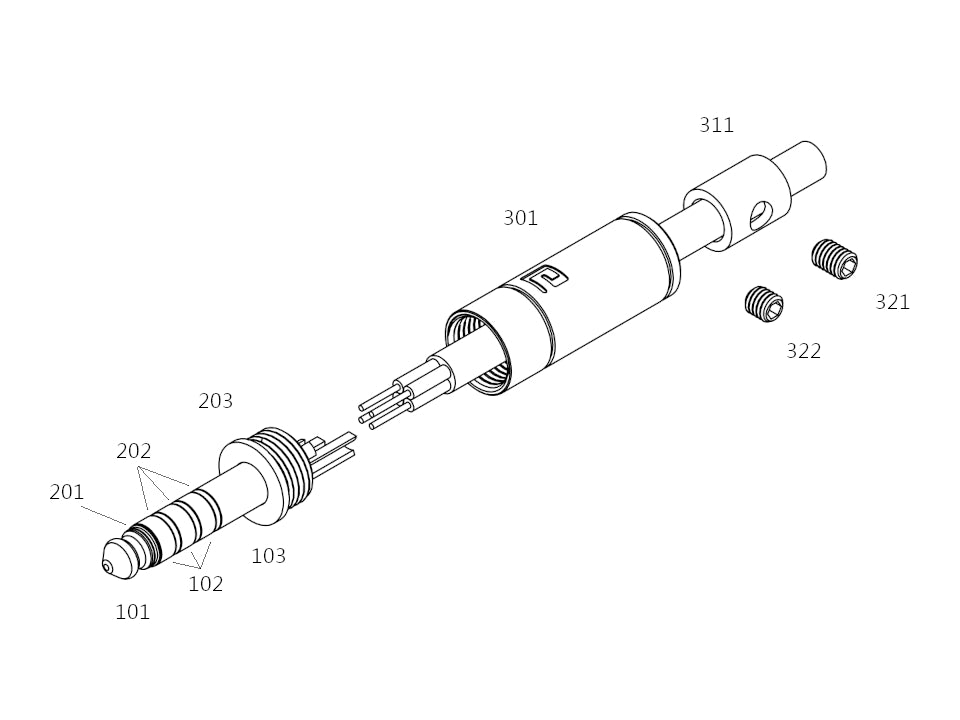

2. Depends on cable size to decide whether use sleeve (ID 4.5mm) [311], or without sleeve (ID6.5MM) [301].Then through into cable.

3. Soldering each channel conductors.

4. The interface of each channel and cable polarity , please find the detail as below picture.

5. Lock the shell and body [203].

6. Please lock the cable and shell with a screw M3x4mm [321] or M3x3mm [322].

Specification

Specification

Material:

Tip Pin: Tellurium Copper (C14500 / copper contains over 99%)

Center ring: Tellurium Copper (C14500 / copper contains over 99%)

End sleeve: Tellurium Copper (C14500 / copper contains over 99%)

Insulator: Nylon (PA66)

Lock head: POM (Black)

Shell: Stainless steel (SUS304)

Sleeve: POM (Black)

Screw: Stainless steel (SUS304)

Finish:

Tip Pin: 10u" Gold plating (no nickel base).

Center ring: 10u" Gold plating (no nickel base).

End sleeve: 10u" Gold plating (no nickel base).

Insulator: None.

Head lock: None.

Shell: None.

Sleeve: None.

Screw: None.

Electrical Characteristics:

Contact resistance < 1.0 mOhm

Dimension:

Biggest OD: 8.90 mm

Total Length: 43.5mm

Cable hole:

Sleeve contained in shell is 4.5mm.

Sleeve not contained in shell is 6.5mm.

Recommend soldering temperature

Recommend soldering temperature

Temperature Soldering Iron, please keep 340 °C within 3~5 second.

Temperature Soldering Iron, please keep 360 °C within 2~3 second.

Product production process comply with RoHS.

This product obtains R.O.C. Patent No. I829461.

Share